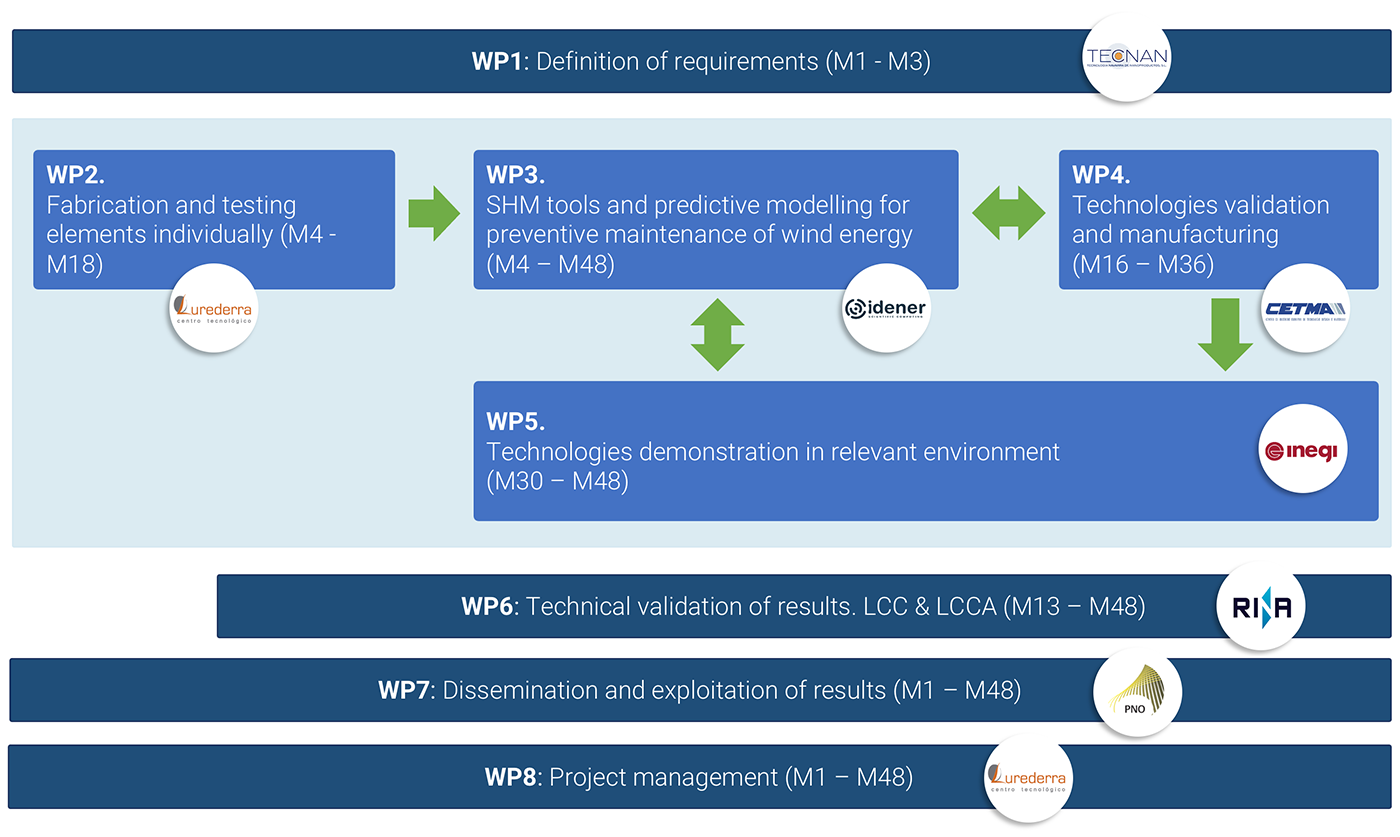

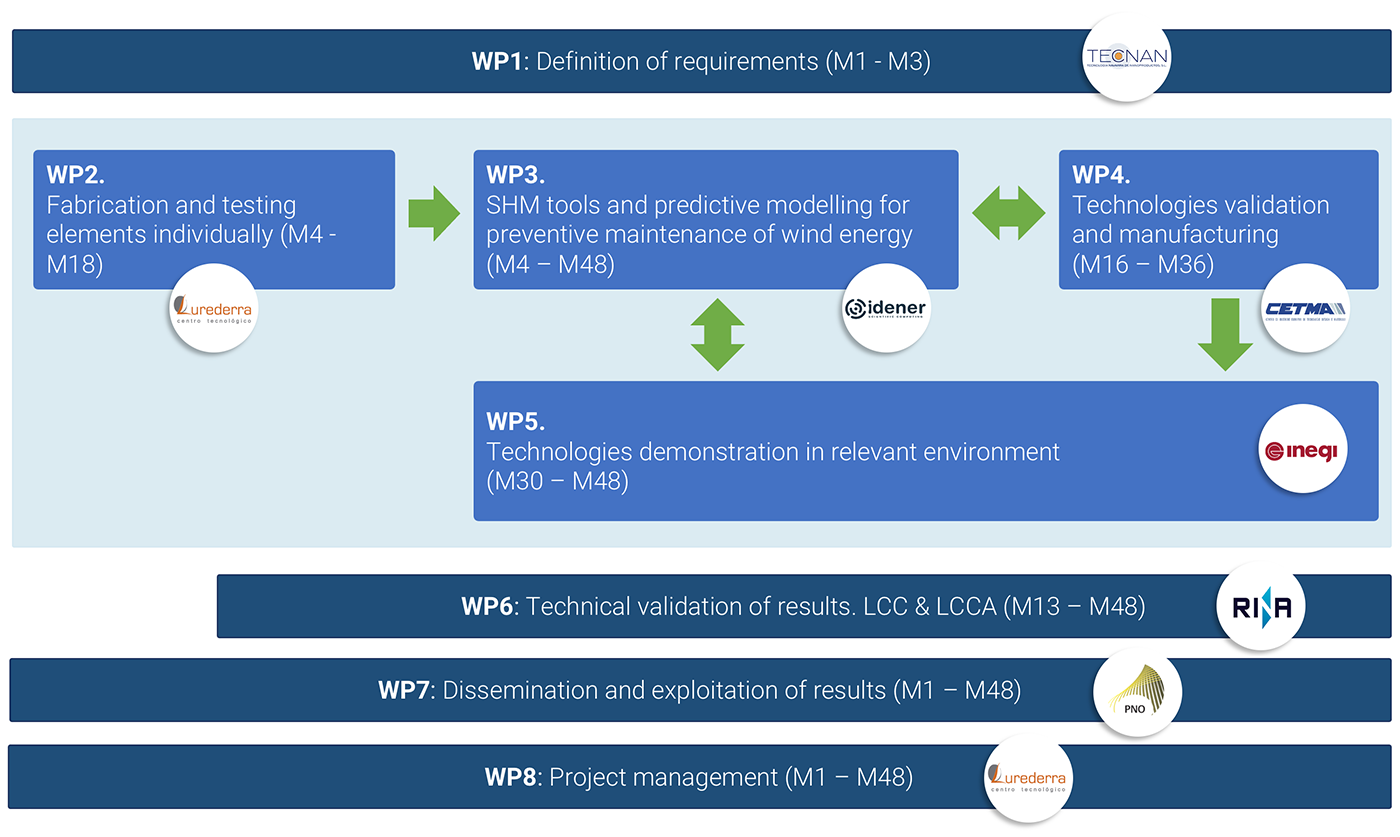

MAREWIND’s implementation plan has 8 work packages, following the general structure below:

WP1: Definition of requirements

Lead by TECNAN, this work package aims to define the requirements and characteristics of new materials, including testing procedures. It will outline and quantify improvements and final properties targeted related to cost, as well as defines sensors types, configuration, full-field techniques requirements. Furthermore, a roadmap for all demonstration sites implementations with identified conditions and required equipment for each predefined demonstration sites.WP2: Fabrication and testing elements individually

LUR will lead WP2 that is designed for formulation, application and optimization at lab-scale coatings for anticorrosion on metallic materials, antifouling for metallic and plastic materials and anti-erosion/superhydrophobic paints for leading edge protection. This WP will also oversee the synthesis and selection of new concrete materials and testing/aging at lab scale. Furthermore, during this phase new composite laminates for wind blades, optimization and testing properties at coupon level will be produced.WP3: SHM tools and predictive modelling for preventive maintenance of wind energy

IDE will lead WP3 that focus on developing and applying full-filed measuring techniques of wind blade working conditions: hardware, measurements and algorithms. WP3 will also carry out implementation and assessment of FBGs/DFOs technologies for composite and concrete representative laboratory components. It will also develop models based on experimental and artificial intelligent algorithms which provides predictions of corrosion rate and protection of coatings in offshore structures at different environmental conditions.WP4: Technologies validation and manufacturing

Main objectives of WP4, led by CETMA, will be:- Validation of selected materials and integration to be tested at relevant environment.

- Optimisation of fabrication and application procedures of materials selected.

- Production of prototypes validated according to manufacturer quality checks.

- Implementing circular use of blade materials at prototype level.

- Obtention of results for final definition of scenarios to be tested in WP5.

- Identification of standard gaps.

WP5: Technologies Demonstration in relevant environment

INEGI will oversee the following objectives:- Build and implement demonstrative prototypes.

- Demonstrate the performance improvement of the validated materials and production processes in WP5 in variety of environments

- Monitor and report the obtained data, as well as assess technical improvements and cost reductions.

WP6: Technical Validation of results LCC, LCCA & SLCA

In WP6 RINA will carry out study on environmental feasibility including life cycle assessment (LCA). It will perform economic validation: Life Cycle Cost Analysis (LCC) and economic feasibility. Furthermore, Social Life Cycle Assessment (SLCA) on health, safety and risk evaluation will be also completed.WP7: Dissemination & Exploitation of Results

PNO will lead WP7 which main aim is to match the project results with market opportunities and make the project’s work widely known. It will promote the project results to variety of stakeholders and ensure uptake of MAREWIND technologies and products by the industry and policy makers. It will also develop an Exploitation and Business plan and assess standardization methodologies to bring project technologies and products into the market.WP8: Project Management

LUREDERA as leader of WP8 will supervise the overall coordination, administrative, financial and contractual management of MAREWID project. As a coordinator of the project, LUR will also act as a coordinator ensuring smooth collaboration and processes within the consortium and project work plan.Slot Online x1000 | Demo Gratis, Anti Lag, Maxwin

Dunia slot online lagi rame. Buat yang pengen ngerasain sensasi maxwin tanpa lag, ini tempatnya. Masuk mode demo gratis, putaran mulus, dan jackpot https://www.marewind.eu/consortium/ seolah manggil buat diambil. Vibenya santai tapi tetap bikin deg-degan enak.Ringkasan Cepat

- Demo gratis untuk pemanasan tanpa risiko

- Anti lag biar fokus ngejar bonus

- Potensi maxwin x1000 kalau timing tepat

Fenomena Slot Gacor

Istilah slot gacor sering dipakai buat nunjukin mesin yang lagi royal https://www.marewind.eu/about-marewind/. Scatter, wild, dan bonus terasa lebih sering muncul. Saat menyentuh maxwin x1000, momen itu biasanya langsung jadi bahan pamer di grup dan story.Tanda-Tanda Gacor

- Beberapa spin awal memberi micro-win beruntun

- Bonus round muncul lebih cepat daripada biasanya

- Simbol kunci seperti wild atau scatter lebih sering aktif

Catatan

Gacor itu dinamis. Kalau sudah mulai hambar, pindah dulu dan coba lagi nanti.Main Demo: Belajar Dulu, Cuan Nanti

Fitur demo membantu pemain memahami pola tanpa keluar biaya. Cocok untuk pemula maupun yang ingin evaluasi game baru.Manfaat Mode Demo

- Gratis dan langsung bisa dimainkan

- Memahami mekanik, pola bonus, dan ritme simbol

- Membandingkan beberapa game untuk menemukan yang paling cocok

Anti Lag Itu Penting

Respons putaran yang cepat menjaga fokus pada interaksi fitur https://www.marewind.eu/contact/. Ritme stabil membuat performa permainan lebih konsisten.Checklist Singkat

- Catat pola free spin yang sering muncul

- Coba nominal virtual yang berbeda

- Berhenti saat sudah paham, lanjut ke mode nyata dengan tenang

Maxwin x1000: Dari Receh Jadi Wow

Maxwin adalah puncak kemenangan dengan pengali besar. Intinya, taruhan bisa berlipat jadi seribu kali ketika kombinasi pas.Ilustrasi

- Taruhan Rp10.000 bisa menjadi Rp10.000.000

- Taruhan Rp20.000 bisa menjadi Rp20.000.000

Realistik dan Terkendali

Tidak semua putaran akan memicu maxwin. Saat kena, simpan momen dan tetap jaga tempo agar tidak terbawa euforia.Langkah Kecil yang Membantu

- Sesuaikan taruhan tipis saat memasuki bonus

- Sisihkan saldo untuk 30 hingga 50 putaran

- Jika ritme berubah, jeda dan evaluasi

Catatan Mini

Mencatat waktu, game, hasil, dan komentar singkat membantu menemukan pola pribadi.Modal Receh, Serunya Segunung

Banyak platform ramah kantong dengan deposit kecil namun fitur tetap lengkap. Ini ideal untuk eksplorasi tanpa khawatir dompet.- Mulai dari nominal kecil sudah bisa bermain

- Bebas berpindah game untuk mencari ritme terbaik

- Bonus, free spin, dan respin tetap tersedia

Strategi Pengelolaan Budget

Bagi saldo menjadi beberapa sesi. Misalnya, porsi eksplorasi, porsi dorong saat momentum, dan porsi cadangan. Sederhana namun membuat napas permainan lebih panjang.Pembayaran Cepat

Sistem pembayaran modern memungkinkan proses yang cepat. Pemain dapat langsung masuk permainan tanpa menunggu lama.Tips Aman

- Simpan bukti transaksi secara pribadi

- Periksa nominal sebelum konfirmasi

- Tetapkan limit harian agar tetap terkendali

Game yang Layak Dicoba

Beberapa gaya permainan sedang naik daun dan patut dijadikan daftar uji.- Slot tema permen dengan efek pecah berantai

- Petualangan mitologi dengan simbol dramatik

- Slot bertema putri dengan potensi hadiah besar

- Buah klasik yang dikemas dengan fitur modern

- Nuansa galaksi neon dengan peluang jackpot berkilau

Mengulik Fitur

Cari game yang menawarkan free spin dengan pengali progresif. Kombinasi ini sering membuka jalan menuju hasil yang mantap.Membaca Gacor Hari Ini

Game yang kemarin adem bisa menjadi panas hari ini. Pantau tren untuk menangkap momentum dengan lebih cepat.- Ikuti komunitas untuk pembaruan harian

- Terapkan batas percobaan per game

- Beralih saat suasana mulai menurun

Template Pencatatan

Catat tanggal, jam, game, nominal, hasil, dan catatan singkat. Tinjau setiap minggu untuk menyesuaikan strategi.Starter Pack

- Mulai dengan mode demo untuk belajar

- Tentukan budget dan patuhi batas

- Periksa RTP sebagai acuan jangka panjang

Mindset Nyaman

- Utamakan hiburan, hasil adalah bonus

- Evaluasi tiap sesi dengan jujur

- Ambil jeda saat kepala terasa panas

Bonus Round

Banyak puncak hasil terjadi di bonus. Kenali pemicu, atur taruhan ketika fitur aktif, dan tetap tenang saat fluktuasi tajam.Jam Panas dan RTP

Beberapa pemain merasa pagi lebih bersahabat, sementara lainnya memilih malam. Cara terbaik adalah menguji keduanya dan melihat data pribadi.Eksperimen Waktu

- Main selama 15 hingga 20 menit di pagi hari

- Ulangi pola yang sama di malam hari

- Bandingkan micro-win dan frekuensi bonus

Kesimpulan Pribadi

Ikuti tren yang muncul dari catatan. Jika tidak ada pola yang jelas, tetap fleksibel dan jangan memaksakan.Gameplay Lancar

Stabilitas tanpa lag menjaga ritme dan konsentrasi. Periksa koneksi, nonaktifkan notifikasi, dan pastikan perangkat siap untuk sesi yang lebih tenang.Checklist Perangkat

- Pastikan baterai cukup atau sambungkan ke daya

- Tutup aplikasi berat di latar belakang

- Gunakan mode jangan ganggu saat bermain

Budaya Jackpot 2025

Slot menjadi bagian dari budaya pop. Pemain berbagi tangkapan layar, melakukan siaran langsung, dan membuat tantangan bersama. Suasana kompetitif hadir, namun suasana kebersamaan juga terasa.Nongkrong Online

- Memberi selamat pada pemain lain yang menang

- Menanyakan rekomendasi game yang sedang naik

- Berbagi cerita nyaris menang untuk melepas tegang